Impact testing of materials to determine their toughness and sensitivity is a critical practice in a variety of industries. For this duty and for determining toughness, there are a number of established approaches that may be used. The Izod Method and the Charpy Method are two examples of such procedures.

In order to determine the strength, toughness, and sensitivity of a material, it is common practice to employ one of these two procedures. A hammer is used to strike the material under test in both procedures, and the height difference before and after striking is recorded, as well as the strength or toughness, to compute its strength or toughness.

To descend from a certain height, the Izod and Charpy techniques use a pendulum with known mass and length that is adjusted to drop from that height.

Izod Vs. Charpy Methods

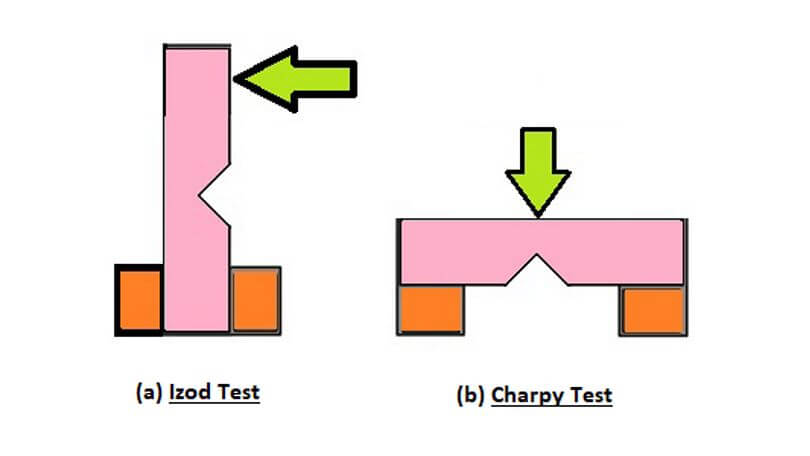

Because the sample notch in the Izod technique always faces the pendulum vertically, the striking point is always located at the higher tip of the sample in the Charpy method, the Izod method is preferred. The Charpy technique is distinguished by the fact that the notch is maintained horizontally away from the pendulum and that the striking point is located in the center of the sample.

What is the Izod Method, and how does it work?

The Izod technique was developed by Gilbert Izod in 1903 and is a kind of impact testing. The approach is used to determine the influence of strain on a material’s life span, which is critical in calculating the material’s service life.

The striker’s notch is maintained vertical and towards the striker’s direction in the Izod technique. The Izod technique has a striking point that is located at the top tip of the material. It merely has a V-shaped notch. The Izod technique may be used to test both metals and polymers, and it is quite versatile.

What is the Charpy Method, and how does it work?

Charpy Impact testing technique was developed by Georges Charpy in 1901 as an improved and standardized method for impact testing utilizing spring-loaded machines. This approach became known as the Charpy Impact testing method after the inventor.

A hammer is struck against the material under test, which is then used to measure the notch sensitivity of the material. The energy received by the material is then used to assess its strength and toughness.

The notch in the Charpy technique is maintained horizontal and pointing away from the pendulum in order to prevent it from swinging. The most notable aspect of it is located in the center of the sample. The Charpy technique is distinguished by the presence of U and V notches.

Difference between the Izod and the Charpy Methods

- In both the Izod and Charpy procedures, a hammer is used to hit the material from a certain height. The energy absorbed by the material is used to compute its toughness, and the material’s sensitivity is used to estimate how sensitive it is to the hammer stroke.

- Secondly, in the Izod approach, the notch is maintained in its vertical position relative to the pendulum, but in the Charpy method, the notch is maintained horizontally in its opposite position relative to the pendulum.

- The Izod technique requires that the substance under test be positioned vertically, while the Charpy method requires that the material under test be put horizontally.

- The striking point of the Izod technique is located at the top tip of the material, while the striking point of the Charpy method is located in the centre of the material

- The Izod technique only has a single notch, which is referred to as the V notch, but the Charpy method has two notches, which are referred to as the U notch and the V notch.

- In the Izod technique, a farming hammer is utilized for hitting, while the Charpy method makes use of a ball pin hammer as the striking tool.

- The Izod technique is utilized for both metals and plastics testing, but the Charpy method is only used for metals testing.

- The equipment used in the Izod technique has common dimensions of 64*12.7*3.2 mm for plastics and 127*11.43 mm round bar for metals, but the equipment used in the Charpy method has dimensions of 55*10*10 mm.

- Among the usual requirements used in the Izod technique are ASTM D256, ASTM E23, and ISO 180, while the common specifications used in the Charpy method include ASTM E23, EN 10045-1, and other similar specifications. 10.

Conclusion

The Izod and Charpy methods vary in that the equipment is adjusted in a different way, although both techniques are employed for the same objective. This kind of procedure involves using the sample to absorb energy, which is then used to compute the toughness of the material, and using the sample to determine the sensitivity of the notch sample. In comprehending the fracture difficulties of diverse materials such as metals and polymers, these approaches are quite useful in a variety of situations.